Brief history

Here a little overview about the set up of ZOTTO and the activities of the last 20 years.

Discontinuous measurements

The village of Zotino, located at the central part of the Jennissey had been selected in 1996 as base for surface measurements because it is located at the boarder between East and West Siberian vegetation.

The surface based measurements indicated a major C-sink of the Siberian ecosystems.

Location of Zotino was chosen

Based on the successful operation of the 400m Wisconsin tower and the establishment of the EU-Chiotto tall tower project as part the CarboEurope cluster it became clear that a key region, where continuous atmospheric GHG-measurements were missing was the boreal region of Siberia.

In parallel to political negotiations, investigations were made about a possible location. The tower should be remote enough from industrial sources, it should not be affected by a large river, and it should oversee a typical fraction of the boreal forest in an area which has been shown to exhibit major temperature change in the past decades.

Based on this science history, Zottino was chosen as a region, and, in order to avoid the effects of the large river, the first rise following the river flood-plain (25 km west of the river) was chosen as ultimate location to house ZOTTO, the ZOtino Tall Tower Observatory

Tower Planning and Investigations

Having the federal Russian government permission didnnot allow to start a building ZOTTO immediately. There were about 35 local institutions which had to agree that a tower was to be erected at the selected spot. Only then, planning by German engineers and construction-ground investigations by a Russian company could start in 2004.

Shipment

Having reached all necessary permits within one year the construction of ZOTTO could in fact start in autumn 2005.

Tower Construction

Major problems were encountered during the hammering of concrete poles into the sand-based construction ground, while the steel construction was uplifted without any problem.

Other things that had to be done in this year:

– Container moving, place in bunker, connecting things

– Set up air conditioning, ELT, UPS

– Commissioning of generators (NTC)

– Diesel connection for generators

– Setting up the measuring containers

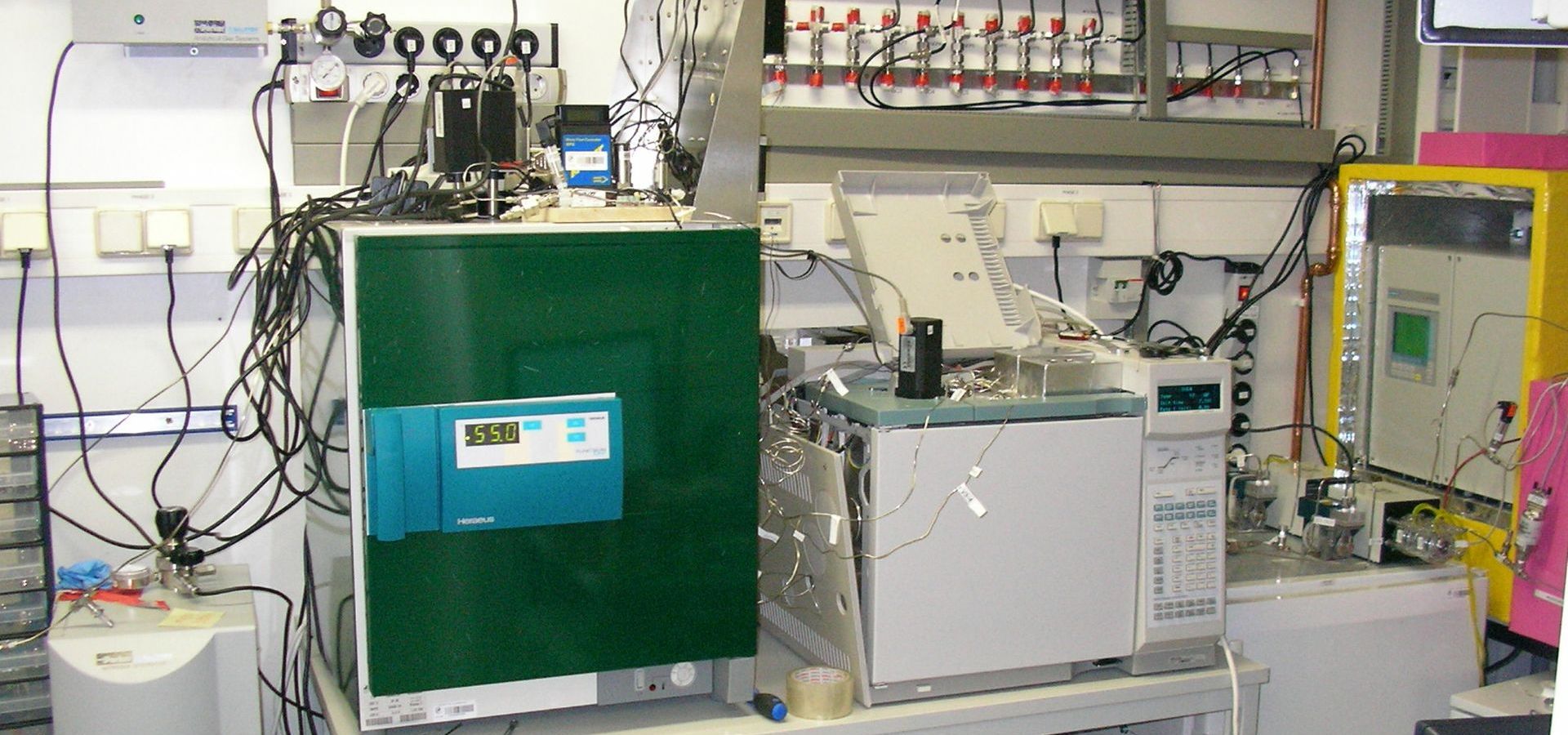

– Installation and commissioning of measuring equipment

– Temporary installation of air intake lines (tower height 54m)

300m Tall Tower

After one year of construction the ZOTTO tall tower was finished in September 2006.

April

The first work was the trial installation of air intakes on the tower and the maintenance measuring system.

The first arrival of calibration gases, which were send from germany, took place and some problems with snowmelt arised in the bunker.

First ascent

In September 2006 the team at ZOTTO was accompanied by moviemakers from Munich, who filmed for the news of ARD and ZDF.

The MPI technicians Karl Kübler, Steffen Schmidt and Michael Hielscher mastered the „First ascent“ up to 304m height.

They prepared the mounting of the meteorology sensors by attaching booms and installing power supply boxes.

The russian Co-workers assembled outriggers and boxes.

People from the IfT in Leipzig set up aerosol measurement installations.

Other important things to do az ZOTTO had been:

– installing air inlets for the tall tower

– dismantling of assembly jib

– building a system for filling working tanks

– the maintenance of the diesel line (settlement through concrete sump)

At the end of the trip the inauguration of the ZOTTO tower was celebrated with the construction company, with people from IoF, BGC MPIC and IfT and of course helpers from Zotino, without whom the whole project would not be possible.

September

May

Maintenance

In 2007 ZOTTO got the ELT acceptance of the station by the engineering office.

In this year we did the iesel maintenance, the grounding of generator container and the dismantling of the tall tower (TT) measuring system and packed it for transport back to Jena.

We had to do modification of the UPS due to the container removal and the removal of 2 other containers.

In this late summer the meteorology of the Zotto tall tower was completed (windbreak for temperature, pressure sensors).

September

May

Maintenance with MC Fire

In 2008 Lutz Wetzel technician from the extern motor company Fire „MC Fire“ helped maintaining and repairing the engine together with Karl Kübler.

Maintenance of meteorology of the ZOTTO tower is always an important task of the trips to Siberia.

Set up meteorology

304m Meteo – Installing Heating Wire to Wind Sonics

304m Meteo: Wiring of components for I/O boxes

304m Meteo: Transport Wind3D to tower and installation

304m Picarro: Closing door openings -> installation area for instruments (from 4 to 2 containers)

304m Picarro: Installation of new air intakes

September

April

Transport new ZOTTO measuring system ZOTTO2 on winter road

Unpacking of the boxes

Setup measuring system ZOTTO2 (304m Picarro) -> PhD Jan Winderlich

304m Picarro: Connecting measuring lines in the bunker

Maintenance

June

September

Maintenance

Winter road

Transport winter road

Unpacking the boxes

Picarro water test

Update Software

Repair air conditioning (change pump, fan motor)

Installation wood moisture logger in the bunker

March

June

Safety concept

Implementation of safety concept

Transport and storage of rescue equipment including equipment (100m, 200m, 300m)

Transport and installation of safety rope for abseiling including outrigger on tower (3x100m)

Maintenance UPS

Determination of EDDY locations forest and swamp

Routing ELT cable for EDDY forest and swamp

Construction EDDY towers in forest and swamp

Generator maintenance by Lutz Wetzel from company Fire

Maintenance climate

Installation ground sensors

Meteo 305m tower

Maintenance Meteo

September

June

Unpacking transport (material bunker sealing

Maintenance pumps ZOTTO2

Installation Wind 2D for reference 304m

Maintenance of generators

Control safety rope as well as the

Maintenance of the meteo tower

Maintenance of cooling system

Installation ground sensors at meteo forest

Mirroring Picarro hard disk

Check wood moisture bunker

Bunker sealing

Russ. Colleagues remove complete sand from bunker

Application, bonding of a 3-piece prefabricated synthetic rubber tarpaulin including all connection points.

Optimization of EDDY-ELT route with GPS

Laying ELT cable to EDDY forest and swamp 3.2km

Laying in the swamp by hand with five people

Maintenance Meteo 304m

Repair abseil safety rope

Application of sand on bunker (climatic buffer)

Installation protective wall against sand erosion

August

October

Maintenance

Maintenance

November

June

Russ. Colleagues Volodya and Anatoly build EDDY huts

Unpacking transport

Attachment of booms and meters, lightning protection to EDDY forest and sump

Installation I/O boxes, loggers, computers for EDDY forest, sump

Connecting and muffling the EDDY ELT cable

Commissioning EDDY forest, sump

Generators: engine replacement

ZOTTO2 cleaning inlet filter at tower and bunker and filter flowmeter

Maintenance EDDY

Inspection of rescue equipment and safety rope at 304m

September

April

EDDY Maintenance and filter change.

Transferring calibration gases for EDDY

EDDY calibration

Air conditioning maintenance

Diesel line maintenance

Geno emergency cooler maintenance

Exchange emergency cooler bunker (3-phase)

ZOTTO2 installation of new flowmeter

Transport of a new dog „May“ for Anatoly😉.

304m tower: transport with pulley new safety rope, 100m stainless steel rope 8mm = 30kg.

EDDY maintenance calibration and filter change.

Meteo ground Forrest new temp sensor.

Briefing of Anastasya and Alexey in EDDY maintenance.

June

September

New Meteo laptop purchased in KJA.

Lightning strike in EDDY ELT main cable, set 2 sleeves

Engine maintenance Reimo, Karl

Repair/maintenance Licor LI-7550 Reimo

Maintenance Meteo

Running down EDDY ELT main cable – recording damages

304m: Measure cable tensions

Karl Kübler and Reimo IFOR KJA: LICOR damage survey and repair.

March

April

Picarro adjustment laser by Steffen Schmidt.

Installation of repaired LICOR by Karl Kübler

EDDY: Maintenance sample pump, Karl Kübler

EDDY: Filter change

EDDY: Maintenance Meteo

EDDY Maintenance Sample System

EDDY: Re-measurement of boom directions

EDDY: Refilling calibration gases 2L-bottles

EDDY Sump: Exchange Temp-Bottom-Senors

EDDY sump: Picarro transport, installation

EDDY Maintenance Meteo Laptop

Maintenance Pumps

304m_Fuse rope torn 200-300m, installation new fuse rope, SteffenSchmidt and Karl Kübler

EDDY ELT main cable run down, sighting damage, repair by Steffen and Karl

many forest fires, no ship back

June

September

Engine maintenance, Lutz Wetzel, Karl

Diesel: new tank, temporary connection, Thomas

Maintenance air conditioning

Maintenance heating house

EDDY KAlibration Licor

Maintenance

March

June

Maintenance

Maintenance

August

September

Maintenance

Trip via winter road by car – Karl Kübler and Steffen Schmidt

EDDY east side: generator hut ventilation with automatic fan control and hand protection

and maintenance Meteo

304m: Maintenance Picarro Computer, Thomas Seifert

EDDY forest: maintenance of profile system and EDDY calibration

UPS maintenance batteries

March

September

Concreting fixed points

Concreting of 4 pillars in the taiga as fixed points for the measurement of stability

Maintenance EDDY east side

Maintenance air-conditioning bunker – Repair recirculation cooler

EDDY east side: remove snow/ice from solar panels

EDDY east side: Geno-Haus installation of automatic supply/return air flaps, motor-controlled, in winter heating of room air -> batteries UPS

EDDY east side: Installation of heat storage tank

March

June

Repair after lightning

304m: Renew cable wind 2D (lightning damage)

304m: Replace tower repeater (lightning damage)

ZOTTO survey: Drilling, gluing the measuring points into foundations

ZOTTO Surveying: Sounding the sighting axes (between fixed points)

ZOTTO survey: stripping of the fixed points

EDDY Maintenance Meteo

Picarro: Synchronise laser

Preparation for surveying

EDDY Maintenance Meteo

304m: Pulley – new safety rope 100m 30kg, clamps for Leica prisms (surveying)

EDDY ELT main cable mend with socket after biting

304m: Maintenance main pumps

Surveying: visual axes from above leveled

Engine maintenance Tobias, Karl EDDY Maintenance Meteo

304m: Pulley – new safety rope 100m 30kg, clamps for Leica prisms (surveying)

EDDY ELT main cable mend with socket after biting

304m: Maintenance main pumps

Surveying: sighting axes from the top

Engine maintenance Tobias, Karl

September

March

EDDY forest – reinstallation Licor

EDDY bog meteo: exchange temperature sensor

EDDY forest Meteo: reinstallation Licor (flow problems)

EDDY Meteo maintenance

EDDY Meteo: calibration Licor

House heating: measurement for pipe reconstruction summer ’18

Bunker USV: maintenance batteries

Surveying: securing elevation fixed point HP0

EDDY Meteo maintenance

EDDY Meteo: Maintenance ELT main cable, run off, bite point taping

EDDY Meteo maintenance, calibration Licor

Surveying: Attachment, alignment of Leica prisms on tower

Surveying: Welding of elevation zero point HP01 as steel girder

Surveying: Marking of all fixed and measuring points

Surveying: Creation, clearing of sighting axes between fixed points

304m: Retrieval of broken safety rope 200-300m

Translated with www.DeepL.com/Translator (free version)

June

August

Measurement of ZOTTO stability

House Heating: Transport of copper fittings for heating pipe conversion PVC->copper

Survey – visual axes, shorten steel support because in visual field

Survey – fixed points, construction of rear-ventilated protective shell -> climate buffer sun position

Measurement of stability: reference measurement of position with Leica total station

and of height with digital leveller

Measurement of stability: 1st monitoring measurement of position with Leica total stationand t of height with digital leveller

EDDY Maintenance -pump repair

EDDY Meteo – Maintenance: filters, exposing profile system, pumps

March

June

EDDY Meteo – Maintenance

EDDY Meteo – Maintenance: Calibration,

EDDY Meteo – ELT main cable run off, taping browsing

304m: safety cable 200-300m extension springs as test

Survey: fixed points – sealing of climate protection pipe

Installation of new safety rope

– Clear cutting of the visual axes of the measuring field in order to do the

2nd control measurement of stability: measurement of position and

measurement of height

Engine maintenance

Tarek helping at ZOTTO and east of the river to the Eddy station

304m: Installation of new safety rope 200-300m

304m: Measuring the rope tension

EDDY maintenance

September

Covid – Pandemic

Due to the corona epidemic, all journeys from germany were cancelled, but the russian colleagues have been very helpful in this difficult time. They sent flasks with airprobes to the labs and did the maintenance of the station